Being certified EN ISO 9001/2015 since 2001 we boast a quality management system that involves all employees from supply to delivery, through all stages of processing, ensuring all our customers’ expectations.

We boast of controls in process and final supported by both management information tools that measuring machines with air-conditioned halls. With the use of the “GALILEO” management system, every detail is handled with a production order with a processing cycle that guarantees traceability at every stage and after the delivery.

Quality and Certifications

We have the following internally:

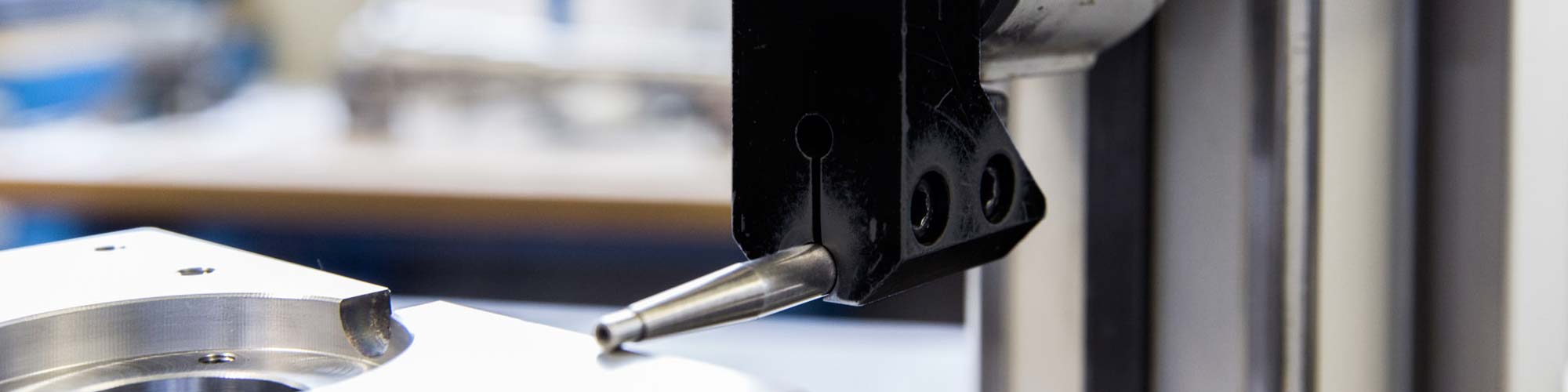

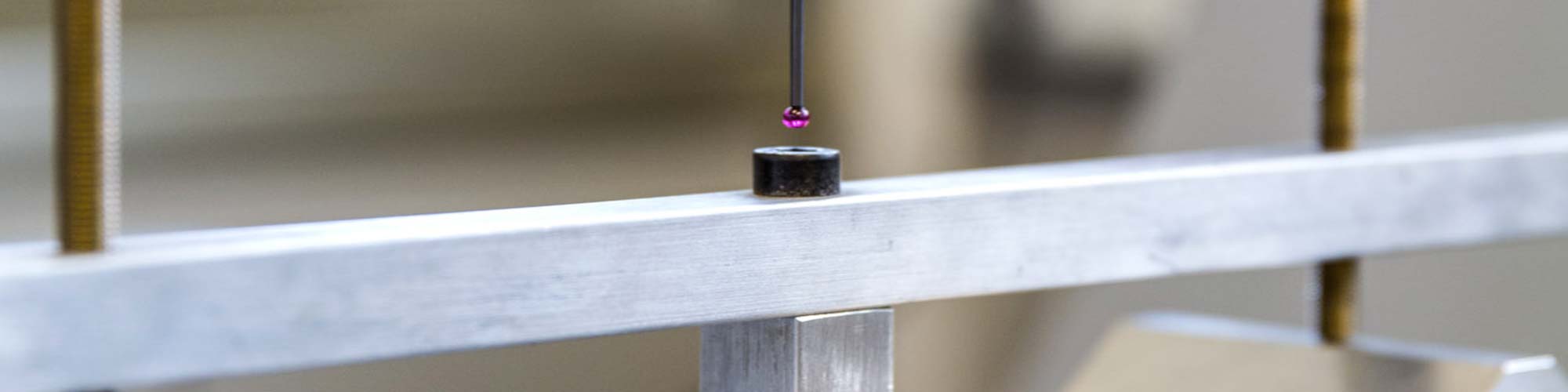

- n. 1 Coordinate Measuring LEITZ REFERENCE Xi – C.N. – Axes Stroke X:1200; Y:2200; Z:1000 in air-conditioned room

- n. 1 Coordinate Measuring DEA GLOBAL PERFORMANCE – C.N. – Axes Stroke X:1200; Y:2200; Z:1000. in air-conditioned room

- n. 1 Coordinate Measuring Machines COORD 3 – C.N. – Axes Stroke mm. 700x550x400. in air-conditioned room

- n. 1 Coordinate Measuring Machines COORD 3 – C.N. – Axes Stroke mm. 1.200x900x700. in air-conditioned room

- 3 altimeters Eley and Warren mod. Vertex h = 800

- 1 Nikon profile projector

- 1 Roughness measurer HOMMELWERK

- 1 Fixed hardness testers for Brinnell hardness control and Rockwell

- 1 Portable hardness tester ERNST for Vickers control, HRC Rockwell and Brinnell

- 1 Recording equipment for MAGNAFLUX

- 1 Air-conditioned room for primary instruments and high precision controls

Click on thumbnail to view large image